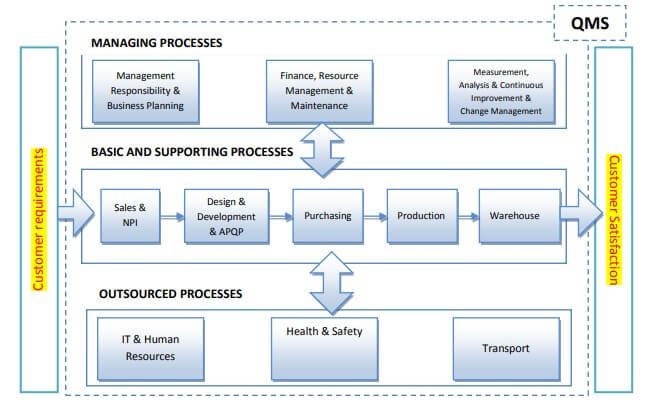

From your initial enquiry and a signed & agreed mutual Non-disclosure Agreement (NDA) we follow the following processes :

New Product Introduction & Contract Management

Design & Development Procedure

APQP Product Realisation

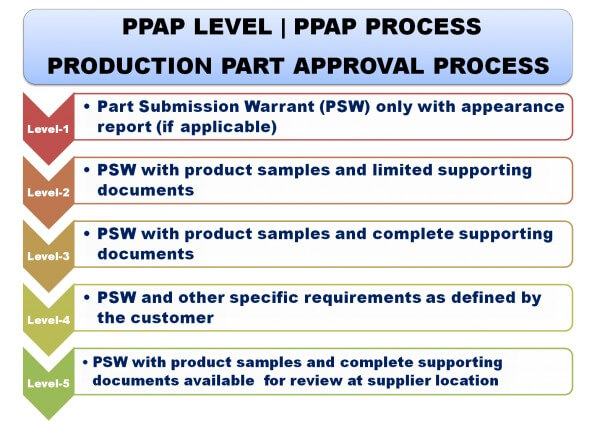

Production Part Approval Process Procedure

Manual Quality Procedure

Business Procedure

Specialist Design & Engineering Services to OEMs with 20 Years of Experience in the Industry

Experience, industry know-how, confidentiality, and attention to detail have all contributed to our enviable reputation for "quality driven innovation".

Adopting industry standard automotive core tools & processes which have been matured for over a century Auto-Kit International are well placed to deal with all eventualities

The automotive core tools & principles we have adopted include:

- A.P.Q.P (Advanced Product Quality Planning)

- P.P.A.P (Production Part Approval Process)

- F.M.E.A (Potential Failure Modes & Effects Analysis)

- M.S.A (Measurement Systems Analysis)

- S.P.C (Statistical Process Control)

- 8D (Eight Disciplines / Problem Solving)