To ensure adhesion integrity Auto-kit International perform the following in-house tests :

Dyne Testing : Dyne-pens with built-in applicators are pulled across the entire web in a straight line. The pens have their dyne level listed on them. As the pen is drawn across the web, the operator looks to see that the solid line does not break for two seconds

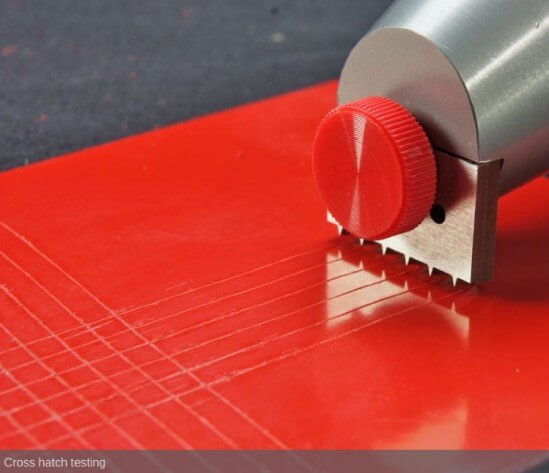

Cross Hatch Test : The cross hatch test is a pattern of right angle cuts in the paint surface through to the substrate. The cracking of line edges and the loss of adhesion of segments is compared with the scale of results listed below. The following information should only be used a guideline for classification of cross hatch test results.

Hot Water Pressure Test (HWPT) : In this the damage that a pressurised water jet can cause is not only dependent on how well the coating adheres. The water pressure, water temperature and duration of jetting influence the degree of damage, as does the distance of the high-pressure nozzle to the component tested, the geometry of the nozzle and the surface area impacted.