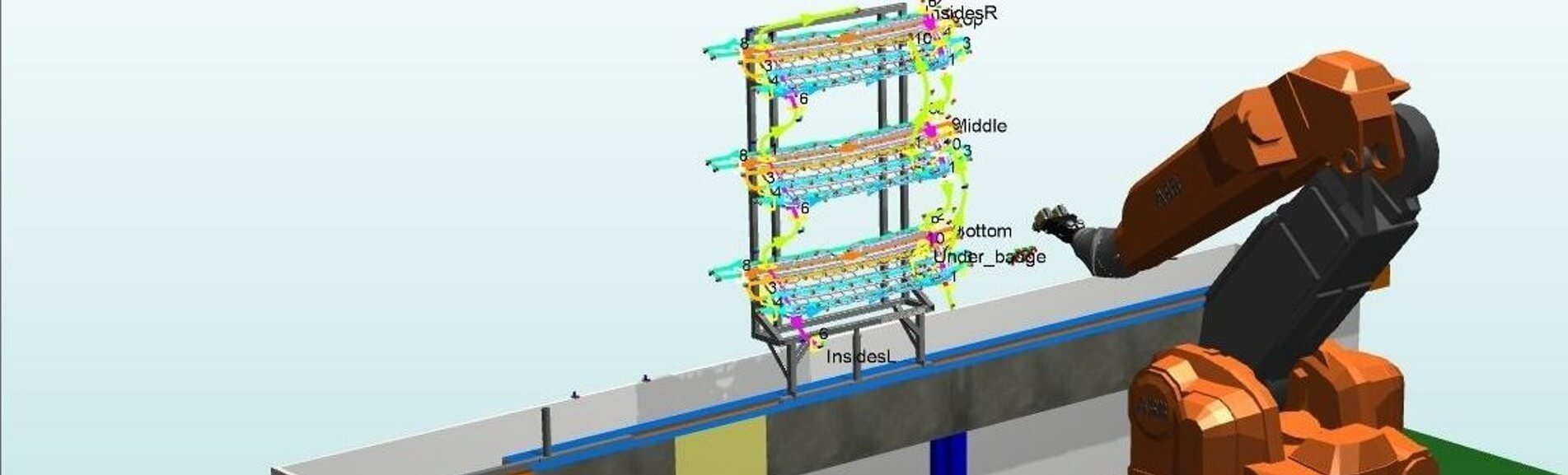

Industrial Robot Programming requires Industry Experience and Tech Expertise

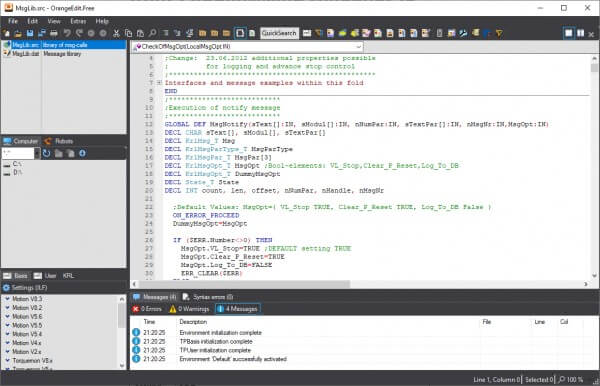

We have expertise in offline & intuitive programming given our industry experience and access to highly qualified programmers.

Robot programming has largely moved away from low level coding to more intuitive methods. This move has partly been fuelled by a desire to make programming easier for operators. Robot operators are not always robot makers, and robot makers are not always the best people to program a particular task. It would, for example, be far better to get a painter to program a painting robot, rather than a programmer who has no experience with painting. Traditional programming methods would be restrictive for such operators.