JIT Production System & EDI

We aim to use Just-in-time production system to produce only the needy products in demanded quantities at the right time in perfect quality. The JIT has been used in mixed-model assembly lines with negligible change-over costs between the products to respond to the customer demands for a variety of models of a common base product without holding large inventories or incurring large shortages.

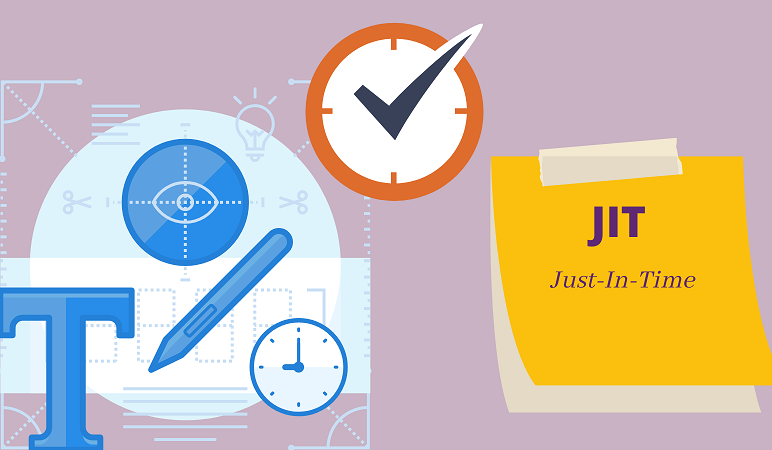

And, Electronic Data Interchange (EDI) is the computer-to-computer exchange of business documents in a standard electronic format between business partners.

By moving from a paper-based exchange of business document to one that is electronic, we enjoy major benefits such as reduced cost, increased processing speed, reduced errors and improved relationships with our business partners.

EDI proves its major business value by lowering costs, improving speed, accuracy and business efficiency. It also helps improve data quality, delivering at least a 30—40% reduction in transactions with errors. Promotes corporate social responsibility and sustainability by replacing paper-based processes with electronic alternatives.

EDI provides the reliable communications that manufacturers require. Some of the benefits include :

- 1. Increased business efficiency through automated transaction workflows and a piece of mind for our customers

- 2. Reduced dependence on manual data entry and a reduced number of data errors

- 3. Expedited order-to-cash, procure-to-pay, and load-tender-to-invoice processes

Benefits of Just-in-time System :

- Continuous quality improvement

- Waste Elimination

- Improve productivity

- Defect free output

‘Buying British’ isn’t about blind patriotism, It goes above and beyond supporting British manufacturing. When you think of British manufacturing, the first word that springs to mind is ‘quality’.

Did you know? - Despite the decline since the 1970s, when manufacturing contributed 25% of UK GDP, the UK is currently the ninth largest manufacturing nation in the world.