Our engineers spend weeks refining and perfecting designs specifically for your seats, headrests and centre consoles. Each custom pattern is tested for precise fit and durability. A design process is an art form - we have to balance and make sure the covers are easy to install while creating the best fit possible. All of our patterns are engineered to meet this goal.

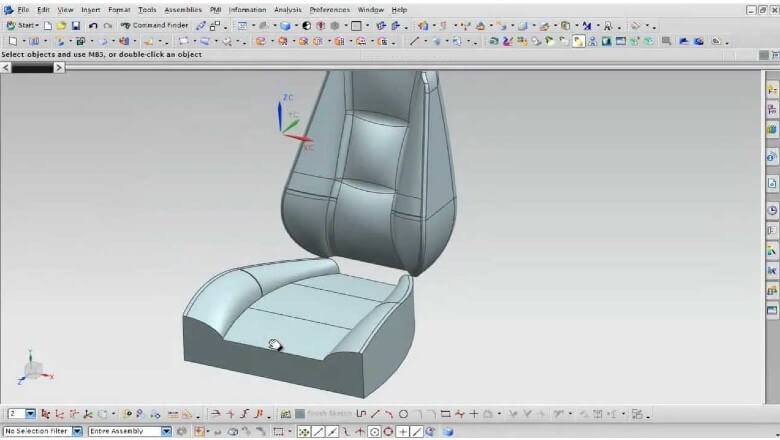

We take the customer's A-surface data and engineer the product ensuring it is designed for manufacture in the most cost-effective way whilst meeting all quality targets. We have full CAE capabilities to optimise the design of the product. Products are engineered on CAD using Catia or Solid Works programmes.

Design Productivity

Our designers select the most appropriate tools and methods for every task, using any combination of 2D and 3D, solid modeling, curve and surface design, parametric feature-based modeling, template-based design, modular design, subdivision modeling and direct modeling functions.